Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

2025-01-03

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

- 1. Introduction to Static Brick Making Machines

- 2. What Are Static Brick Making Machines?

- 3. Key Benefits of Using Static Brick Making Machines

- 4. Operational Efficiency: How They Work

- 5. Cost-Effectiveness of Static Brick Production

- 6. Sustainability and Environmental Impact

- 7. Technological Advancements in Static Brick Making

- 8. Conclusion

- 9. FAQs

1. Introduction to Static Brick Making Machines

In the ever-evolving world of construction, efficiency and sustainability are paramount. The advent of **static brick making machines** has transformed traditional methods of brick production. These machines signify a shift towards more efficient and environmentally conscious practices, catering to the growing demands of modern construction. In this article, we dive deep into the mechanics, benefits, and advancements surrounding static brick making machines, revealing why they are essential to the future of construction.

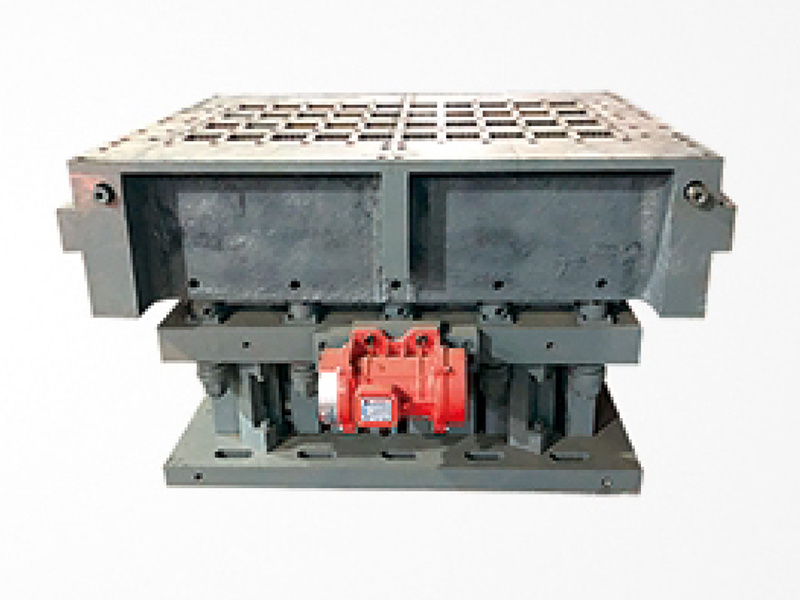

2. What Are Static Brick Making Machines?

Static brick making machines are sophisticated devices designed to produce bricks in a stationary manner. Unlike their mobile counterparts, these machines remain in one place and utilize hydraulic pressure to mold raw materials into bricks. The primary components of static brick making machines include:

- **Molding Chamber**: This is where the mixture is shaped into bricks.

- **Hydraulic System**: It applies pressure to the mixture for compaction and forming.

- **Control Panel**: Operators can manage the machine's functions through this interface.

By leveraging advanced technology, static brick making machines offer higher precision in the production process, ensuring consistent quality and dimensions in every brick produced.

3. Key Benefits of Using Static Brick Making Machines

The benefits of static brick making machines are numerous, making them a preferred choice in the construction industry:

3.1 Improved Quality Control

Static machines provide greater control over the production process, ensuring uniformity in brick size and strength. This leads to decreased waste and higher quality in construction projects.

3.2 Increased Production Efficiency

With their high-speed operation, static brick making machines can produce a significant number of bricks in a short period. This efficiency leads to quicker project completions.

3.3 Automation and Labor Savings

Many static machines come equipped with automation features that minimize manual labor. This not only reduces labor costs but also lowers the risk of workplace accidents.

3.4 Versatility in Production

These machines can produce various types of bricks, from standard clay bricks to specialized ones like fly ash bricks and interlocking pavers, catering to different construction needs.

4. Operational Efficiency: How They Work

Understanding the operational efficiency of static brick making machines is crucial. The process involves several key steps:

4.1 Material Preparation

Raw materials, typically clay, sand, and additives, are mixed in precise proportions to create a homogenous mixture. This step is vital for achieving the desired properties in the final product.

4.2 Molding

The prepared mixture is fed into the molding chamber. The hydraulic system exerts high pressure, compacting the mixture into the desired brick shape.

4.3 Curing

After molding, the bricks undergo a curing process where they are allowed to harden. This is often done in controlled environments to ensure optimal strength and durability.

4.4 Quality Testing

Post-curing, bricks are subjected to rigorous quality testing to ensure they meet industry standards. This may include compressive strength tests and dimensional accuracy checks.

5. Cost-Effectiveness of Static Brick Production

Static brick making machines are not only efficient but also cost-effective. Here’s how they contribute to overall savings:

5.1 Reduced Production Costs

With the ability to produce bricks at a high volume, costs per unit decrease substantially. The automation of processes further cuts down labor costs.

5.2 Longevity and Maintenance

Investing in a static brick making machine can yield long-term benefits. Their robust design ensures durability, and regular maintenance can extend their lifespan, leading to lower replacement costs.

5.3 Energy Efficiency

Many models are designed to consume less energy while maintaining high production rates. This efficiency translates into lower utility costs for manufacturers.

6. Sustainability and Environmental Impact

Sustainability is a growing concern in construction, and static brick making machines align well with eco-friendly practices:

6.1 Use of Recycled Materials

These machines can utilize recycled materials, such as fly ash and other industrial waste, in their production processes. This not only reduces landfill waste but also minimizes the extraction of raw materials.

6.2 Reduced Carbon Footprint

Static machines often operate with lower emissions compared to traditional brick firing methods, contributing to a reduced carbon footprint for construction projects.

6.3 Energy-efficient Operations

By employing advanced technologies, these machines optimize energy use, further supporting sustainable construction initiatives.

7. Technological Advancements in Static Brick Making

The evolution of technology in static brick making machines has led to remarkable enhancements that further improve efficiency and output:

7.1 Smart Automation

The integration of IoT and smart technology allows for real-time monitoring and control of the manufacturing process, leading to enhanced operational efficiency and reduced downtime.

7.2 Enhanced Material Processing

Innovations in material processing technology enable the use of a broader range of raw materials, improving the versatility of brick production.

7.3 Data-Driven Quality Control

Machine learning algorithms help automate quality control processes, analyzing data to predict potential defects and ensure that only top-quality bricks reach the market.

8. Conclusion

The construction industry is witnessing a significant transformation with the introduction of static brick making machines. These machines not only enhance operational efficiency but also promote sustainability and cost-effectiveness. By embracing the advancements in technology, builders and manufacturers can meet the increasing demands of modern construction while minimizing their environmental impact. As we move forward, static brick making machines will play a pivotal role in shaping a more efficient and sustainable future for the industry.

9. FAQs

9.1 What is the primary advantage of static brick making machines?

The primary advantage is their ability to produce high-quality bricks quickly and efficiently, significantly reducing production costs and time.

9.2 How do static brick making machines compare to mobile machines?

Static machines offer higher precision and quality control, while mobile machines provide flexibility for on-site production.

9.3 What types of bricks can be produced using static machines?

Static machines can produce various types, including clay bricks, fly ash bricks, concrete blocks, and interlocking pavers.

9.4 Are static brick making machines environmentally friendly?

Yes, they can utilize recycled materials and operate with lower emissions, contributing to more sustainable practices in construction.

9.5 What should I consider when purchasing a static brick making machine?

Consider factors such as production capacity, energy efficiency, automation features, and the range of materials it can process.

Relevant Information

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31