Understanding Vibration Block Making Machines and Their Role in Construction

2025-01-08

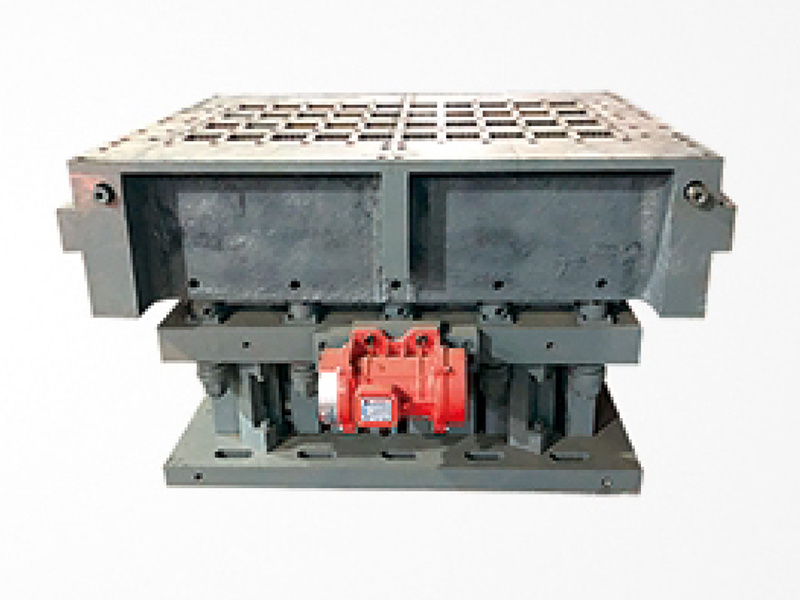

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the concrete mixture is compacted effectively, resulting in stronger, more durable products.

One of the primary advantages of using a vibration block making machine is the efficiency it brings to the production process. The machine operates by mixing raw materials—such as cement, sand, and aggregates—before vibrating the mixture into molds. This vibration helps eliminate air pockets and ensures that the concrete fills the molds uniformly, enhancing the integrity of the final product. Consequently, the blocks produced are not only aesthetically pleasing but also exhibit superior strength and stability, making them suitable for various construction applications.

Another essential aspect of vibration block making machines is their ability to improve the consistency of the blocks produced. Manual production methods can lead to variations in size, shape, and density, which can compromise the quality of the finished product. In contrast, vibration block making machines utilize precise measurements and automated processes, ensuring that each block meets specified standards. This uniformity is crucial in large-scale construction projects, where inconsistencies can lead to structural issues or increased material waste.

Furthermore, these machines can be configured to create a variety of block types, from solid concrete blocks to hollow blocks, making them versatile assets for manufacturers. By adjusting the vibration frequency, pressure, and curing time, operators can customize the blocks to meet specific design and load-bearing requirements. This flexibility not only caters to diverse construction needs but also enhances the competitiveness of manufacturers in the market.

Sustainability is another important consideration in the production of bricks and blocks. Modern vibration block making machines can incorporate recycled materials, reducing waste and minimizing the environmental impact of construction processes. As sustainability becomes an increasingly critical factor in the industry, manufacturers who utilize these machines can contribute to greener practices while still producing high-quality products.

In summary, vibration block making machines play a crucial role in the construction and decorative materials sector by ensuring the efficient production of high-quality concrete blocks. Their ability to provide consistency, versatility, and sustainable practices makes them indispensable for builders and manufacturers alike. As the industry continues to evolve, investing in advanced technologies such as vibration block making machines can enhance productivity and meet the growing demands for durable building materials.

One of the primary advantages of using a vibration block making machine is the efficiency it brings to the production process. The machine operates by mixing raw materials—such as cement, sand, and aggregates—before vibrating the mixture into molds. This vibration helps eliminate air pockets and ensures that the concrete fills the molds uniformly, enhancing the integrity of the final product. Consequently, the blocks produced are not only aesthetically pleasing but also exhibit superior strength and stability, making them suitable for various construction applications.

Another essential aspect of vibration block making machines is their ability to improve the consistency of the blocks produced. Manual production methods can lead to variations in size, shape, and density, which can compromise the quality of the finished product. In contrast, vibration block making machines utilize precise measurements and automated processes, ensuring that each block meets specified standards. This uniformity is crucial in large-scale construction projects, where inconsistencies can lead to structural issues or increased material waste.

Furthermore, these machines can be configured to create a variety of block types, from solid concrete blocks to hollow blocks, making them versatile assets for manufacturers. By adjusting the vibration frequency, pressure, and curing time, operators can customize the blocks to meet specific design and load-bearing requirements. This flexibility not only caters to diverse construction needs but also enhances the competitiveness of manufacturers in the market.

Sustainability is another important consideration in the production of bricks and blocks. Modern vibration block making machines can incorporate recycled materials, reducing waste and minimizing the environmental impact of construction processes. As sustainability becomes an increasingly critical factor in the industry, manufacturers who utilize these machines can contribute to greener practices while still producing high-quality products.

In summary, vibration block making machines play a crucial role in the construction and decorative materials sector by ensuring the efficient production of high-quality concrete blocks. Their ability to provide consistency, versatility, and sustainable practices makes them indispensable for builders and manufacturers alike. As the industry continues to evolve, investing in advanced technologies such as vibration block making machines can enhance productivity and meet the growing demands for durable building materials.

Relevant Information

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31