- Inquiry

PRODUCTS

Xiexing Machinery

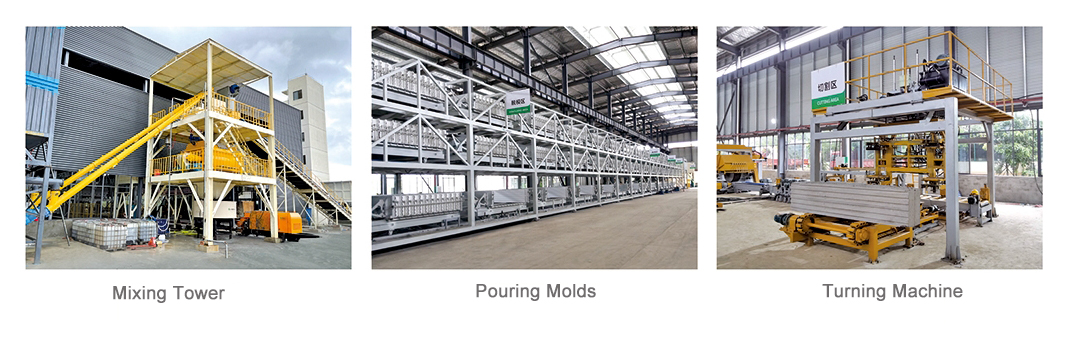

Ceramsite Foam Concrete Block Procution Line

- NAME: Ceramsite Foam Concrete Block Procution Line

Mobile & Whatsapp: 8613489892777

Online inquiry

Detailed Introduction

Ceramsite Foam Concrete Block Procution Line

As a new type of lightweight building material, ceramic block has the following comprehensive advantages:

1、 Excellent structural performance

Lightweight and High Strength: Low density (ceramic aggregate packing density<400kg/m ³), can reduce the self weight of buildings by about 1/3, while possessing compressive strength (up to 900kgf/m ²) and seismic performance (about 63KSC).

Durable and stable: Strong fire resistance (meeting Class A fire protection standards), weathering resistance, impermeability and frost resistance, with a service life of over 50 years.

2、 Outstanding functional features

Thermal insulation: With low thermal conductivity, it meets 65% of the building's energy-saving requirements and has a significant effect of keeping warm in winter and cool in summer.

Sound insulation and absorption: The 90mm thick wall panel has good sound insulation effect and is suitable for indoor and outdoor sound insulation needs.

Waterproof and moisture-proof: The porous structure prevents condensation and has superior anti mold and anti-corrosion properties.

3、 Construction efficiency and economy

Convenient construction: The mortise and tenon structure does not require batch plastering, and tiles/wallpaper can be directly pasted, with a construction speed four times faster than traditional methods.

Cost optimization: Reduce overall costs by 30-70%, reduce transportation costs (only one-third of red bricks) and structural loads.

4、 Environmental Protection and Sustainability

Energy saving and environmental protection: Production does not require steam pressing process, utilizing industrial waste (such as fly ash) to reduce resource consumption and pollution.

Recycling: The materials are recyclable and in line with the trend of green and low-carbon development.

Through the above characteristics, ceramic aggregate blocks are widely used in frame building walls, old house renovation partition walls, and integrated insulation and decoration projects.

Our Foam Block Making Machine is engineered for precision, durability, and high-volume production of foam blocks used in packaging, insulation, and construction industries. Designed with advanced automation technology, this machine ensures consistent foam density, smooth cutting accuracy, and optimal energy efficiency. It supports various foam materials, including EPS (Expanded Polystyrene), EPP (Expanded Polypropylene), and PU (Polyurethane), catering to diverse manufacturing needs.

Foam block making machine Key features include a fully automated cutting system, adjustable block dimensions (customizable up to 6m in length), and a high-speed expander for uniform foam bead distribution. The PLC-controlled interface allows for easy operation, reducing manual labor while maximizing output. With a robust hydraulic compression system, it produces tightly compressed foam blocks with minimal material waste. Safety mechanisms, such as overheat protection and emergency stop functions, ensure reliable and secure operation.

Ideal for large-scale foam production plants, this machine delivers low maintenance costs, fast cycle times, and superior block consistency. Optional add-ons include integrated recycling systems for scrap foam reuse, enhancing sustainability. Trusted by global manufacturers, our Foam Block Making Machine guarantees productivity, precision, and long-term performance—making it the ultimate solution for high-quality foam block fabrication.

Keyword:

best foam block making machine

Online Inquiry

Please make sure to leave your correct contact information so that we can contact you easily!