Why Investing in a Solid Block Making Machine Can Transform Your Manufacturing Process

2024-12-14

Why Investing in a Solid Block Making Machine Can Transform Your Manufacturing Process

Table of Contents

1. Introduction to Solid Block Making Machines

2. The Importance of Quality in Concrete Manufacturing

3. Key Features of Modern Solid Block Making Machines

4. Benefits of Investing in a Solid Block Making Machine

4.1. Enhanced Production Efficiency

4.2. Cost Savings and Profitability

4.3. Improved Product Quality

4.4. Versatility and Customization Options

5. Technological Advancements in Block Making Machines

6. How to Choose the Right Solid Block Making Machine

6.1. Assessing Your Production Needs

6.2. Evaluating Machine Specifications

6.3. Understanding Maintenance and Support

7. Case Studies: Successful Implementation of Block Making Machines

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Solid Block Making Machines

Investing in a solid block making machine is a strategic move for any business involved in the manufacturing or construction industry. These machines are designed to produce high-quality concrete blocks, essential for various construction projects. With the increasing demand for durable building materials, understanding the benefits of solid block making machines is crucial for any manufacturer looking to expand their capabilities and improve their product offerings.

2. The Importance of Quality in Concrete Manufacturing

Quality is the cornerstone of any successful manufacturing process, especially in the concrete industry. The durability and strength of concrete blocks directly impact the longevity and safety of structures. By using a solid block making machine, manufacturers can ensure a consistent quality of blocks, which is vital for maintaining reputation and meeting regulatory standards in construction.

3. Key Features of Modern Solid Block Making Machines

Modern solid block making machines are equipped with various features that enhance their functionality and efficiency. These may include:

- **Automated Controls:** Allow for precise mixing and molding processes.

- **High Production Capacity:** Capable of producing numerous blocks within a short time frame.

- **Energy Efficiency:** Designed to minimize energy consumption while maximizing output.

- **Robust Build Quality:** Ensures longevity and durability under continuous use.

These features not only increase production rates but also reduce the overall cost per unit, making them a smart investment for manufacturers.

4. Benefits of Investing in a Solid Block Making Machine

The advantages of incorporating a solid block making machine into your manufacturing process are manifold:

4.1. Enhanced Production Efficiency

One of the most significant benefits of investing in a solid block making machine is the increase in production efficiency. Automated processes reduce labor costs and minimize human error, allowing for a smoother operation and higher output levels. Manufacturers can meet the growing demands of the construction sector without compromising on quality.

4.2. Cost Savings and Profitability

While the initial investment in a solid block making machine may seem substantial, the long-term savings are undeniable. By improving production efficiency and reducing waste, manufacturers can significantly lower their operating costs. The ability to create high-quality blocks at a lower price point allows businesses to remain competitive in the market.

4.3. Improved Product Quality

Investing in a solid block making machine ensures that the blocks produced meet stringent quality standards. The uniformity and consistency in production lead to fewer defects and rejections, ultimately resulting in a higher-quality product that meets industry specifications.

4.4. Versatility and Customization Options

Modern solid block making machines offer a range of customization options, enabling manufacturers to produce various block types and sizes. This versatility allows businesses to cater to diverse customer needs and adapt to changing market demands.

5. Technological Advancements in Block Making Machines

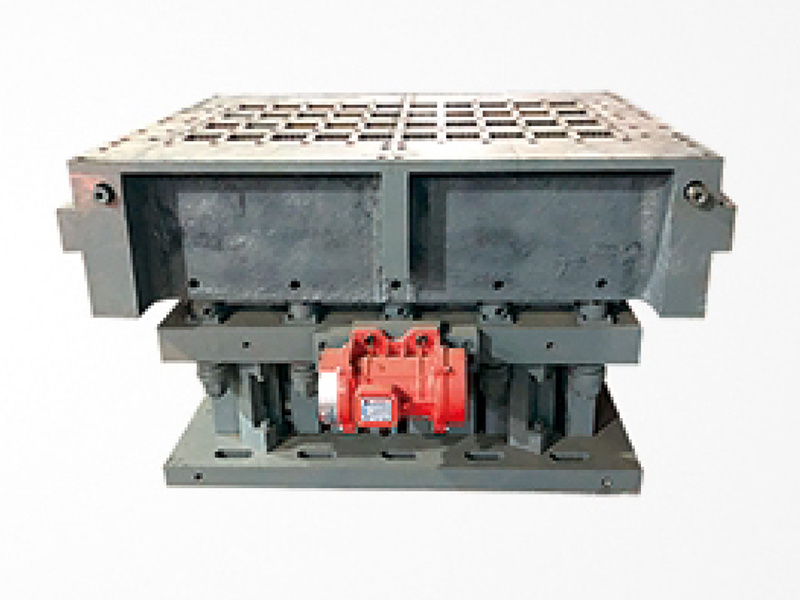

Technological advancements have greatly influenced the design and functionality of solid block making machines. Innovations such as **computerized controls, advanced hydraulic systems, and eco-friendly technology** contribute to improved efficiency and sustainability in the manufacturing process. Staying updated with these advancements is essential for businesses aiming to maintain a competitive edge.

6. How to Choose the Right Solid Block Making Machine

Selecting the appropriate solid block making machine is crucial for optimizing production. Key considerations include:

6.1. Assessing Your Production Needs

Before making a purchase, it is vital to evaluate your production requirements. Consider factors such as the expected output, block specifications, and the scale of your operations.

6.2. Evaluating Machine Specifications

Review the technical specifications of potential machines, including their production capacity, power consumption, and automation features. This information will help you identify a machine that aligns with your operational goals.

6.3. Understanding Maintenance and Support

Investing in a solid block making machine involves ongoing maintenance and support. Choose a manufacturer that offers comprehensive service options and readily available replacement parts to ensure minimal downtime.

7. Case Studies: Successful Implementation of Block Making Machines

Several companies have reaped the benefits of investing in solid block making machines. For instance, a mid-sized construction firm incorporated a state-of-the-art machine into its operations and experienced a **30% increase in production efficiency** within the first six months. Additionally, they reported significant cost savings due to reduced labor requirements and material waste.

8. Frequently Asked Questions (FAQs)

**Q1: What is the average lifespan of a solid block making machine?**

A: Most solid block making machines can last over 10 years with proper maintenance.

**Q2: Can I produce different types of blocks with one machine?**

A: Yes, many modern machines come with customizable molds, allowing you to produce various block types.

**Q3: How much space is required for a solid block making machine?**

A: The space required can vary based on the machine size and production capacity. It is advisable to consult the manufacturer for specific requirements.

**Q4: Are solid block making machines energy-efficient?**

A: Yes, modern machines are designed to be energy-efficient, helping reduce operational costs.

**Q5: What are the maintenance requirements for these machines?**

A: Regular maintenance includes checking hydraulic systems, lubricating moving parts, and ensuring proper calibration of controls.

9. Conclusion

Investing in a solid block making machine is a transformative step for any manufacturer looking to enhance their production processes. With improved efficiency, cost savings, and superior product quality, the benefits far outweigh the initial investment. As the construction industry continues to evolve, staying ahead with advanced machinery will ensure long-term success and competitiveness. Embracing this technology not only meets current market demands but also paves the way for future growth and innovation.

Relevant Information

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31