Unlocking the Potential of Cinder Block Making Machines for Your Construction Projects

2024-12-19

Cinder block making machines are essential equipment in the construction industry, particularly for producing concrete blocks used in various structural applications. These machines work by mixing raw materials such as cement, aggregates, and water, then molding this mixture into blocks that can be used for building walls, foundations, and other structures. The process is efficient and can produce a large number of blocks in a relatively short time, making it a preferred choice for contractors and builders.

One of the main advantages of using a cinder block making machine is the speed at which production can occur. With automation and advanced technology, these machines can significantly reduce labor costs and time associated with manual block production. This efficiency not only accelerates project timelines but also allows builders to maintain a steady supply of materials.

Moreover, cinder block making machines can produce blocks of different sizes and shapes, providing versatility to adapt to various construction needs. Whether you require standard-sized blocks for walls or custom designs for unique architectural features, these machines can be adjusted to meet specific requirements. This adaptability can be a game changer for construction projects that demand precision and creativity.

Sustainability is another critical aspect of using cinder block making machines. By utilizing recycled materials in the production process, such as industrial byproducts or crushed concrete, the environmental impact can be minimized. This not only helps in reducing waste but also promotes the use of eco-friendly practices in the construction industry. Many contractors are increasingly looking for ways to incorporate sustainable materials into their projects, and cinder blocks produced with these methods can play a significant role.

It is also worth mentioning that while investing in a cinder block making machine requires initial capital, the long-term savings and benefits often outweigh the costs. Builders can achieve better quality control over the blocks produced and ensure they meet specific strength and durability standards, which is crucial for safety and longevity in construction.

In conclusion, cinder block making machines are transforming the landscape of construction materials by offering a more efficient, versatile, and sustainable option for producing concrete blocks. As the industry continues to evolve, those who leverage this technology will likely find themselves at a competitive advantage, capable of delivering high-quality projects that meet the demands of modern construction. Whether you are a contractor, builder, or involved in any aspect of construction, understanding the capabilities and benefits of cinder block making machines can help you make informed decisions for your projects.

One of the main advantages of using a cinder block making machine is the speed at which production can occur. With automation and advanced technology, these machines can significantly reduce labor costs and time associated with manual block production. This efficiency not only accelerates project timelines but also allows builders to maintain a steady supply of materials.

Moreover, cinder block making machines can produce blocks of different sizes and shapes, providing versatility to adapt to various construction needs. Whether you require standard-sized blocks for walls or custom designs for unique architectural features, these machines can be adjusted to meet specific requirements. This adaptability can be a game changer for construction projects that demand precision and creativity.

Sustainability is another critical aspect of using cinder block making machines. By utilizing recycled materials in the production process, such as industrial byproducts or crushed concrete, the environmental impact can be minimized. This not only helps in reducing waste but also promotes the use of eco-friendly practices in the construction industry. Many contractors are increasingly looking for ways to incorporate sustainable materials into their projects, and cinder blocks produced with these methods can play a significant role.

It is also worth mentioning that while investing in a cinder block making machine requires initial capital, the long-term savings and benefits often outweigh the costs. Builders can achieve better quality control over the blocks produced and ensure they meet specific strength and durability standards, which is crucial for safety and longevity in construction.

In conclusion, cinder block making machines are transforming the landscape of construction materials by offering a more efficient, versatile, and sustainable option for producing concrete blocks. As the industry continues to evolve, those who leverage this technology will likely find themselves at a competitive advantage, capable of delivering high-quality projects that meet the demands of modern construction. Whether you are a contractor, builder, or involved in any aspect of construction, understanding the capabilities and benefits of cinder block making machines can help you make informed decisions for your projects.

Relevant Information

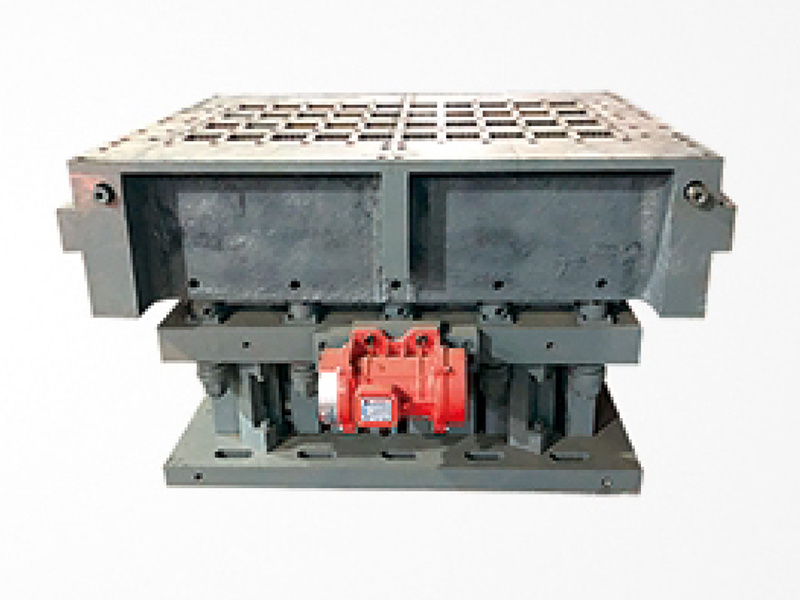

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31