Unlocking Efficiency: The Benefits of Using a Cinder Block Making Machine

2024-12-24

Unlocking Efficiency: The Benefits of Using a Cinder Block Making Machine

Table of Contents

1. Introduction to Cinder Block Making Machines

2. What is a Cinder Block?

3. Why Efficiency Matters in Construction

4. How Cinder Block Making Machines Work

5. Benefits of Using Cinder Block Making Machines

- Cost Savings

- High-Quality Production

- Environmental Benefits

- Labor Efficiency

6. Applications of Cinder Blocks in Construction

7. Choosing the Right Cinder Block Making Machine

8. FAQs about Cinder Block Making Machines

9. Conclusion

Introduction to Cinder Block Making Machines

In today’s rapidly evolving construction industry, efficiency is paramount. A **cinder block making machine** embodies this efficiency, revolutionizing how we produce one of the most essential building materials. These machines not only streamline the manufacturing process but also enhance the quality and sustainability of construction projects. In this article, we will explore the various benefits of using a cinder block making machine, examining how it can dramatically improve productivity and cost-effectiveness in the construction sector.

What is a Cinder Block?

Cinder blocks, also known as concrete masonry units (CMUs), are rectangular blocks made from a mixture of cement, water, and aggregates such as sand or gravel. They are widely used in construction for building walls, foundations, and various structural applications due to their durability and versatility. Cinder blocks can be solid or hollow, providing flexibility in design and function. The uniformity and strength of these blocks make them a preferred choice for both residential and commercial buildings.

Why Efficiency Matters in Construction

In an industry where time is money, **efficiency** plays a crucial role in successful projects. Efficient processes reduce waste, lower costs, and improve overall productivity. In construction, where labor and materials account for a substantial portion of expenses, maximizing efficiency can lead to significant financial savings. By implementing advanced technologies such as cinder block making machines, businesses can enhance their operational capabilities and stay competitive in the market.

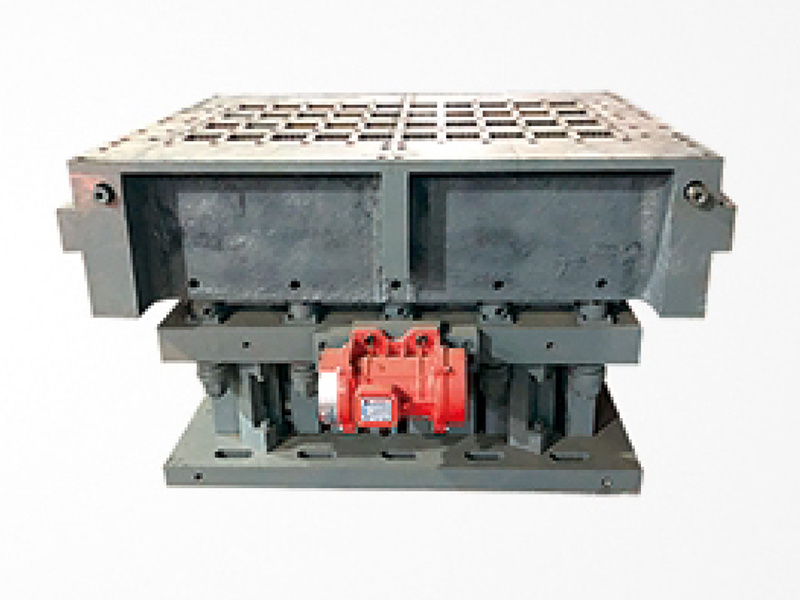

How Cinder Block Making Machines Work

Cinder block making machines operate by mixing raw materials and molding them into blocks. The process typically involves several steps:

1. **Material Mixing**: The machine combines cement, aggregates, water, and any additives to create a homogenous mixture.

2. **Molding**: The blended materials are then poured into molds, which shape them into cinder blocks.

3. **Vibration and Compaction**: Machines use vibration and hydraulic pressure to compact the mixture, ensuring uniform density and strength.

4. **Curing**: After molding, the blocks need to cure, allowing them to harden and gain strength. This process can be accelerated using steam or heat.

Modern cinder block making machines are automated, enhancing precision, reducing labor costs, and increasing production speed.

Benefits of Using Cinder Block Making Machines

Utilizing a cinder block making machine offers numerous advantages, which we will explore in detail.

Cost Savings

One of the primary benefits of investing in a **cinder block making machine** is the substantial cost savings it offers. By producing blocks in-house, companies can eliminate the need to purchase pre-manufactured blocks, which can be expensive. Additionally, the automated process reduces labor costs, as fewer workers are required to operate the machinery compared to manual block-making methods. Over time, these savings can significantly impact a company's bottom line.

High-Quality Production

Cinder block making machines ensure a high level of quality control in the production process. The precise mixing and compaction techniques used by these machines result in uniform blocks with consistent strength and durability. This consistency reduces the risk of defects, leading to fewer construction issues and the need for repairs down the line. As a result, projects completed with high-quality cinder blocks can withstand the test of time.

Environmental Benefits

Sustainability is a growing concern in the construction industry. Cinder block making machines can contribute to environmentally friendly practices. By using recycled materials and minimizing waste during production, these machines help reduce the ecological footprint of construction projects. Furthermore, cinder blocks are energy-efficient in their insulation properties, contributing to lower energy costs for heating and cooling buildings.

Labor Efficiency

Labor efficiency is critical in the construction sector, where skilled labor can be hard to find. Cinder block making machines automate much of the block production process, allowing companies to maximize output with minimal labor. This not only reduces dependency on skilled labor but also enables workers to focus on other essential tasks on the construction site, improving overall project timelines.

Applications of Cinder Blocks in Construction

Cinder blocks are incredibly versatile and find applications in various construction projects:

- **Residential Buildings**: Used in foundations, walls, and even as decorative elements for aesthetic appeal.

- **Commercial Structures**: Essential for creating sturdy and durable commercial spaces.

- **Retaining Walls**: Perfect for landscaping and soil erosion prevention.

- **Sound Barriers**: Effective for noise reduction in urban areas.

- **Firewalls**: Ideal for creating fire-resistant barriers in buildings.

The adaptability of cinder blocks makes them a go-to choice for builders and architects alike.

Choosing the Right Cinder Block Making Machine

Selecting the right cinder block making machine is crucial for maximizing production efficiency and meeting project demands. Consider the following factors:

1. **Production Capacity**: Determine the volume of blocks needed to meet your project's requirements.

2. **Automation Level**: Assess the level of automation that fits your operational needs. Fully automated machines can increase efficiency but may require a higher initial investment.

3. **Quality of Output**: Research machines that produce blocks of consistent quality and strength.

4. **Maintenance and Support**: Opt for machines that offer reliable customer support and have a good reputation for durability.

Investing time in selecting the right equipment can lead to long-term benefits.

FAQs about Cinder Block Making Machines

1. How much does a cinder block making machine cost?

The cost of cinder block making machines varies widely based on factors such as automation level, production capacity, and brand. Prices can range from a few thousand to several tens of thousands of dollars.

2. What materials are needed to produce cinder blocks?

To produce cinder blocks, you will need cement, aggregates (such as sand or gravel), water, and optional additives to enhance strength and durability.

3. Can cinder block making machines be used for other types of blocks?

Yes, many machines are versatile and can be adjusted to produce other concrete products, including bricks and pavers.

4. What is the average production time for cinder blocks?

The production time depends on the machine's capacity and the curing process. Typically, a well-automated machine can produce several hundred blocks per hour.

5. Are there maintenance requirements for cinder block making machines?

Yes, regular maintenance is essential for optimal performance. This includes lubricating moving parts, inspecting for wear and tear, and ensuring the electrical systems are functioning correctly.

Conclusion

In conclusion, utilizing a **cinder block making machine** presents numerous benefits that can significantly enhance construction efficiency and quality. From substantial cost savings and high-quality production to environmental advantages and improved labor efficiency, these machines are pivotal in modernizing the construction process. As the industry continues to evolve, leveraging such innovative technology will not only help businesses stay competitive but also contribute to sustainable building practices. Investing in a cinder block making machine is a strategic move for any construction business looking to unlock efficiency and thrive in a challenging market.

Relevant Information

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31