Understanding Static Brick Making Machines: An Essential Guide for the Construction Industry

2024-12-29

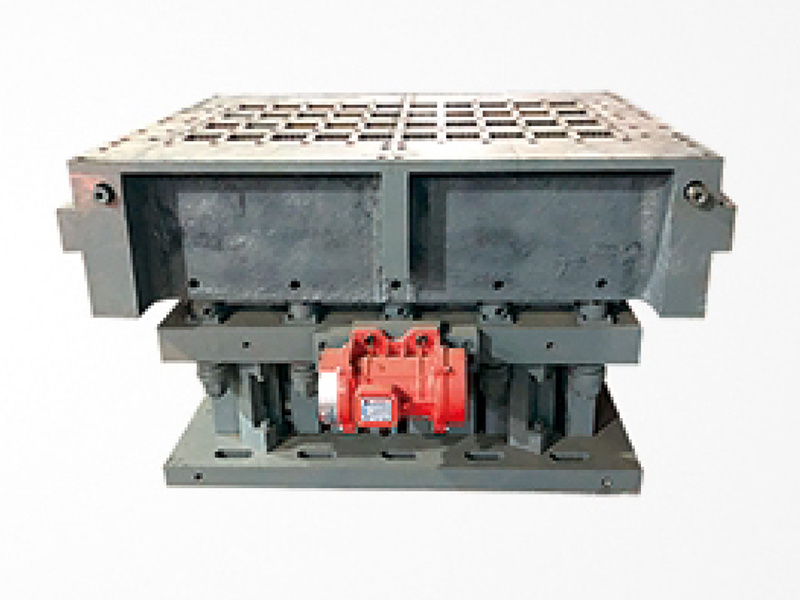

Static brick making machines are integral to the construction and decorative materials industry, specifically in the realm of brick and stone products. These machines are designed to produce concrete or clay bricks without the need for an external energy source, relying instead on static pressure for the compression process. This method allows for the creation of durable and high-quality bricks suitable for a wide range of construction applications.

One of the primary benefits of static brick making machines is their efficiency. Unlike traditional methods that may require extensive labor and time, static machines can produce a significant number of bricks in a shorter period. This efficiency translates to reduced labor costs and faster project completion times, making them an attractive option for construction companies looking to optimize their operations.

Additionally, static brick making machines are known for their consistency in brick quality. The static pressing technique ensures that each brick is uniformly compacted, leading to bricks that meet specific strength and durability standards. This is crucial in construction, where the integrity of the materials used directly impacts the safety and longevity of structures.

Another important aspect of static brick making machines is their environmental impact. Many of these machines are designed to work with recycled materials, such as industrial waste or by-products, which contributes to sustainable building practices. By using recycled inputs, builders can minimize waste and reduce the carbon footprint of their projects. Furthermore, the ability to produce bricks on-site can significantly lower transportation emissions, as materials do not have to be moved over long distances.

Operators of static brick making machines benefit from straightforward maintenance requirements. These machines are typically user-friendly and can be operated with minimal training, allowing companies to quickly integrate them into their production processes. Routine maintenance does not require specialized skills, making it easier for businesses to keep their machines in optimal working condition.

In conclusion, static brick making machines serve as vital tools in the construction and decorative materials sector. Their efficiency, consistency, and eco-friendly capabilities make them an excellent choice for modern construction needs. By choosing static machines, builders can enhance their productivity, ensure high-quality output, and contribute to sustainable practices within the industry. Whether for residential projects or large-scale commercial developments, understanding the advantages of static brick making machines can empower stakeholders to make informed decisions that benefit both their operations and the environment.

One of the primary benefits of static brick making machines is their efficiency. Unlike traditional methods that may require extensive labor and time, static machines can produce a significant number of bricks in a shorter period. This efficiency translates to reduced labor costs and faster project completion times, making them an attractive option for construction companies looking to optimize their operations.

Additionally, static brick making machines are known for their consistency in brick quality. The static pressing technique ensures that each brick is uniformly compacted, leading to bricks that meet specific strength and durability standards. This is crucial in construction, where the integrity of the materials used directly impacts the safety and longevity of structures.

Another important aspect of static brick making machines is their environmental impact. Many of these machines are designed to work with recycled materials, such as industrial waste or by-products, which contributes to sustainable building practices. By using recycled inputs, builders can minimize waste and reduce the carbon footprint of their projects. Furthermore, the ability to produce bricks on-site can significantly lower transportation emissions, as materials do not have to be moved over long distances.

Operators of static brick making machines benefit from straightforward maintenance requirements. These machines are typically user-friendly and can be operated with minimal training, allowing companies to quickly integrate them into their production processes. Routine maintenance does not require specialized skills, making it easier for businesses to keep their machines in optimal working condition.

In conclusion, static brick making machines serve as vital tools in the construction and decorative materials sector. Their efficiency, consistency, and eco-friendly capabilities make them an excellent choice for modern construction needs. By choosing static machines, builders can enhance their productivity, ensure high-quality output, and contribute to sustainable practices within the industry. Whether for residential projects or large-scale commercial developments, understanding the advantages of static brick making machines can empower stakeholders to make informed decisions that benefit both their operations and the environment.

Relevant Information

Understanding Vibration Block Making Machines and Their Role in Construction

Vibration block making machines are vital tools in the construction and decorative materials industry, particularly within the realm of brick and stone manufacturing. These machines are designed to produce concrete blocks, paving stones, and various other types of masonry products that are widely used in construction projects. By harnessing the power of vibration, these machines ensure that the co

2025-01-08

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Transforming Construction: The Unmatched Efficiency of Static Brick Making Machines

Table of Contents

1. Introduction to Static Brick Making Machines

2. What Are Static Brick Making Machines?

3. Key Benefits of Using Static Brick Making Machines

4. Operational Efficiency: How They Work

5. Cost-Effectiveness of Static Brick Production

6. Sustainability and Environmental Imp

2025-01-03

Our Hollow Brick Mold is a cutting-edge solution designed to meet the growing demand for sustainable, energy-efficient construction materials. Made from durable, high-quality steel or aluminum

2024-12-31